Technologies

We have always worked to give the best to our customers, to differentiate ourselves from our competitors and to achieve a high degree of competitiveness by offering complete services. Over the years, all this has allowed us to acquire important know-how in different machining and heat treatment technologies, along with a wide range of capabilities in a variety of products and sizes.

Our latest technologies investment strategy as well as our innovation and commitment to the evolution within Industry 4.0, allows us

to offer high-tech processes to our customers.

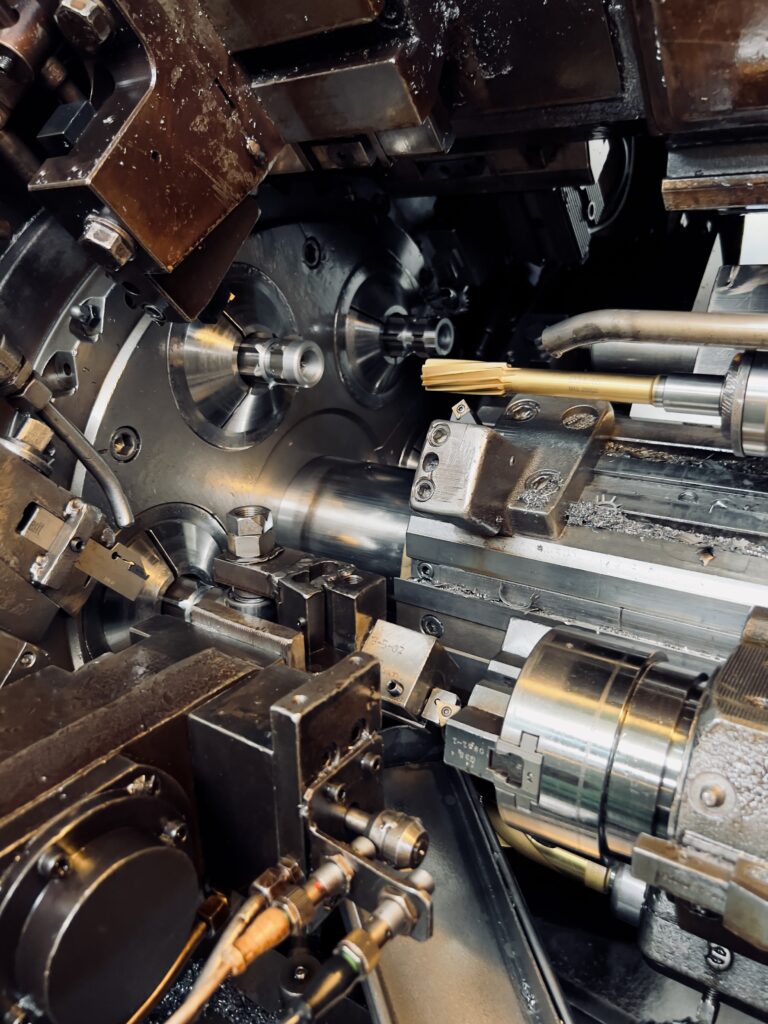

Multi-spindle machining

Multi-spindle cam and numerical control machining from diameters of 12 mm to 75 mm.

Machining on CNC bar lathes

Machining on single-spindle CNC lathes up to diameters of 75 mm, two spindle and sliding heads with diameter capacities up to 32 mm.

Machining on CNC lathes with chucks

Machining on CNC lathes with double-spindle chucks and automatic loads, with diameter capacities up to 250mm.

Broaching

Broaching of straight and helical interiors with multi-station machines, with fully automated feeds and diameters up to 65 mm.

External fluting

Various external fluting machines up to module 2.

Centreless and tangential grinding

We carry out different (through-feed or plunge) grinding processes on CNC centreless grinding machines up to diameters of 150 mm and CNC tangential grinding.

Machining Centres

We carry out different processes with 3 and 5-axis machining centres.

Hard Turning

Different high-quality machines for hard machining with high-precision finishes.

Special Machines

Special machines for second operations and 100% automatic checks.

Product Washing

We are equipped with the necessary cleaning solution for each product, from drum, tunnel and modified alcohol processes.

Heat treatments

At ICT we carry out heat treatments by induction, case and quench hardening, as well as nitriding and nitrocarburising.

Assemblies

Carrying out small assemblies with automatic machines and assembly of sub-assemblies.

Technologies

We have always worked to give the best to our customers, to differentiate ourselves from our competitors and to achieve a high degree of competitiveness by offering complete services. Over the years, all this has allowed us to acquire important know-how in different machining and heat treatment technologies, along with a wide range of capabilities in a variety of products and sizes.

Our latest technologies investment strategy as well as our innovation and commitment to the evolution within Industry 4.0, allows us

to offer high-tech processes to our customers.

Multi-spindle machining

Multi-spindle cam and numerical control machining from diameters of 12 mm to 75 mm.

Machining on CNC bar lathes

Machining on single-spindle CNC lathes up to diameters of 75 mm, two spindle and sliding heads with diameter capacities up to 32 mm.

Machining on CNC lathes with chucks

Machining on CNC lathes with double-spindle chucks and automatic loads, with diameter capacities up to 250mm.

Broaching

Broaching of straight and helical interiors with multi-station machines, with fully automated feeds and diameters up to 65 mm.

External fluting

Various external fluting machines up to module 2.

Centreless and tangential grinding

We carry out different (through-feed or plunge) grinding processes on CNC centreless grinding machines up to diameters of 150 mm and CNC tangential grinding.

Machining Centres

We carry out different processes with 3 and 5-axis machining centres.

Hard Turning

Different high-quality machines for hard machining with high-precision finishes.

Special Machines

Special machines for second operations and 100% automatic checks.

Product Washing

We are equipped with the necessary cleaning solution for each product, from drum, tunnel and modified alcohol processes.

Heat treatments

At ICT we carry out heat treatments by induction, case and quench hardening, as well as nitriding and nitrocarburising.

Assemblies

Carrying out small assemblies with automatic machines and assembly of sub-assemblies.